Free Diy Cnc Software

Do you want to be a better CNC’er in 37 Seconds? Get Better Tool Life, Surface Finish, and Material Removal Rates Fast. Click Add-ins tab Import SKP File, or enter IMPORTSKP, to display the Select SKP File dialog box. Note: In AutoCAD 2015 and earlier, apps are located on the Plug-ins tab. Navigate to and select a SketchUp file in a local or shared folder. Click Open to import the file as a block. Sketchup import autocad 2016. The SketchUp Import plug-in allows you to import SKP files into your AutoCAD® drawings. Use the IMPORTSKP command to convert a SketchUp file, stored in a local or shared folder, and insert the model into the current drawing. Solution: There is a free add-on application for AutoCAD versions 2013 and newer which will allow for the importation of SketchUp (SKP) files. When you use the SketchUp Import application to import SKP files into your AutoCAD-based product. Compatible with AutoCAD 2016 versions: SketchUp Import 2016: 3D Warehouse Import 2016: Older versions are not being updated. SketchUp Import – compatible with AutoCAD 2014 & 2015 products. Apr 03, 2017 It is possible to import a project you have already created in another program, such as AutoCAD, into SketchUp. This feature allows you to directly import AutoCAD drawings and DXF files into. It’s that easy. You can install and get results now. |

- Best Cnc Software For Diy

- Carbide Create Diy Cnc Software - Free

- Free 3d Cnc Router Software

- Best Free Cnc Software

- Free Diy Cnc Software Free

- Cnc Programs Free Download

CNC code generator is a software to generate CNC codes (G & M codes) for maching operations like milling, drilling. At present CNC code generator is limited for end milling. We working on other machining operations like turning, drilling etc.

Quick: What’s the Best Free CAD Software out there? How about the Best Free CAM Software?

Apr 29, 2017 Scan2CAD isn’t just a conversion software, it’s also a great source for anything CAD, CAM and CNC-related. It’s not surprising then, that we offer our own cut-ready CNC designs that are free and ready to use with your CNC machines. Jun 19, 2018 Best CAD CAM Software for CNC Beginners, DIY, and Hobbyists 2018 Let’s face it–there’s a lot to learn as you’re starting out in CNC. And, given that CNC is all about computer-controlled machine tools, a lot of that learning has to do with software. Anyone new to the field will have to get an understanding.

We can help! Here’s your guide to the best free CNC software that’s out there. Some of it is ours, some is from 3rd parties.

Is “Free” The Right Choice?

This may seem an odd way to get started, but I need to ask the question in all seriousness. You may have heard the expression, “There ain’t no such thing as a free lunch.”

Sometimes free is totally awesome and there are no strings attached. Other times free makes us choose vastly inferior solutions. We spend so much time fighting with the free software that in the end, had we spent just a little bit, we might have come out a lot better. And sometimes free has sneaky hidden costs.

Keep all that in mind as you check out our choices for the best Free CNC Software you can find.

CNCCookbook Free CNC Software

We always provide a free trial for our software. In addition, when we’re introducing new products, we release them for free while in Beta test and don’t charge until we finish the software. Typically you use it for many months if not a year or two when that happens. We don’t believe in shipping software until it is great. In addition to all that, some of our software is filled with a ton of free features even if you never subscribe.

So checkout our free stuff!

G-Wizard Calculator

We do a terrible job advertising it, but most of G-Wizard Calculator is free. Seriously. You sign up for the free trial, and when that ends, even if you don’t purchase, most of the tabs will go right on working for you. There’s a giant treasure trove of useful calculators, utilities, and reference information there including:

- Fancy scientific calculator with automatic unit conversions and much more.

- The ultimate productivity hack for busy people–the same ToDo list with Pomodoro timer system I use myself to get all this crazy stuff done for CNCCookbook.

- Geometry and Trig Calculators for Right Triangles, Oblique Triangles, Bolt Circles, Dovetails, Tapers, Chamfers, Drilling, Chords, True Position, Points, Turner’s Cubes

- Fits and Tolerances for ISO 286, ANSI B4.2, and DIN 7172

- Thread Database with all the dimensions, tapping drills, and more

- Drill Chart

- Fastener Database with dimensions for Socket Head and Flat Head Cap Screws

- Weights and Volumes for standard metal structural shapes as well as standard lumber sizes

- Thermal Expansi0n Calculator

- Electrical Ohms Law Calculator

- Resistor Color Codes

- CNC Servo and Stepper Motor Sizing Calculators

- G- and M-Code Quick Reference

- Hardness Quick Reference with Rockwell (A, B, C, D, 15H, 30H, 45N), Brinell (Std, Hultgren, Tungsten), Vickers, and Shore scales

- Rigidity Calculator to help figure your tool rigidity

- Chatter Calculator to figure the right spindle speed to stop chatter

- Geometric, Dimensioning, and Tolerancing Quick Reference

Phew! I can hardly keep up with all of it myself. I know there a lifetime subscribers who are still delighted at the new things they discover. And we just keep adding more all the time!

I thought I’d make a quick video showing how it all works:

All of this will save you time digging through machinery’s handbook or trying to Google for it. It’s all stuff that I use constantly and you will love having it at your fingertips. So what are you waiting for–give the G-Wizard free Trial a try:

[ I Savvy, Get Me My Free Trial Now! ]

BTW, you have the choice of buying the software outright (lifetime subscription) or subscribing. Now I hear all the time from hobbyists who don’t think they can afford G-Wizard. First thing is that one year is cheap–not much more than a single cutter costs. But okay, let’s suppose you still think that’s too expensive. The thing is, at the end of that 1 year,Feeds and Speeds keep right on working too.

What’s the catch?

The catch is that once the subscription expires, there’s a spindle power limit equal to 1 horsepower for each year you subscribe. This is perfect for a hobbyist. A small CNC Router may not be able to use more than a 1 horsepower cut–tiny machines just aren’t rigid enough. That means a lifetime of Feeds and Speeds, limited to 1 HP, for just the cost of 1 year of subscription. It’s perfect for the hobbyist trying to save.

And, if you ever get a more powerful machine, just re-subscribe to unlock the limit. No muss, no fuss.

Here you can create the content that will be used within the module.

G-Wizard Editor

Everybody who tries G-Wizard Editor loves it because it’s the first G-Code software whose focus is on simplifying g-code, and it’s also the first to build in Conversational CNC. With conversational CNC, you can work without using CAD. Just answer a few simple questions and GW Editor will write the g-code for you. It’s for all those jobs you were thinking would be faster on a manual machine, and it’s a totally free additional module you get with G-Wizard Editor.

Free DXF Files

[ Get my Free DXF Files Now! ]

Download our free DXF files and be cutting cool patterns on your CNC Laser, Router, Waterjet, or other machine before you know it.

More Free CNC Software

Best Free CAD Software

Which one of these packages is your pick for the Best Free CAD Software out there?

| A9 CAD | CAD | http://www.a9tech.com/products/a9cad/ |

| Blender | CAD | https://www.blender.org/ |

| Draftsight | CAD | https://www.solidworks.com/product/draftsight |

| eCabinet: CAD for custom cabinet makers | CAD | http://www.ecabinetsystems.com/ |

| gCAD3d | CAD | http://www.cadcam.co.at/freiter/gCAD3D_en.htm |

| FreeCAD | CAD | https://www.freecadweb.org/ |

| Google Sketchup | CAD | https://sketchup.google.com/ |

| Fusion 360 | CAD + CAM | https://www.autodesk.com/products/fusion-360/students-teachers-educators |

| GraphiteOne CAD | CAD | https://www.graphiteone-cad.com/ |

| HeeksCAD | CAD | https://github.com/Heeks/heekscad |

| Minos | CAD | http://www.le-boite.com/minos.htm |

| nanoCAD | CAD | https://nanocad.com/ |

| OnShape | CAD | https://www.onshape.com/ |

| Solid Edge Free 2D Drafting | CAD | http://www.solidedge.com/free2d/ |

| TinkerCAD | CAD | https://www.tinkercad.com/ |

| Wings 3D | CAD | https://www.wings3d.com/ |

Free CNC CAM Software

| Estlcam | CAM | http://www.estlcam.com/ |

| Free Mill: 3D Milling from the makers of Visual Mill | CAM | http://www.mecsoft.com/freemill.shtml |

| DeskProto | CAM | https://www.deskproto.com/products/free-ed.php |

| HSMExpress | CAM | http://www.hsmworks.com/hsmxpress/ |

| Fusion 360 | CAD + CAM | https://www.autodesk.com/products/fusion-360/students-teachers-educators |

| G-Simple | CAM | https://www.gsimple.eu/ |

| Heeks CAD/CAM | CAM | https://www.heeks.net/ |

Other Free CNC Software

| GCode Ripper | Wrap GCode for 4th Axis or do Engraving on Irregular Surfaces after Probing | See article link |

| LinuxCNC / EMC2 | Free CNC Control Software | https://www.linuxcnc.org/ |

| Jedicut | CNC Foam Cutting | http://www.aeropassion.net/index-en.php |

| Ace Converter | DXF to G-Code | http://www.dakeng.com/ace.html |

| 2linc Engraving Software: Light Version | Engraving Software | http://www.2linc.com/cnc_programming_software.htm |

| DeskEngrave | Engraving Software | http://www.deskam.com/download.html |

| PCB-GCODE | G-Code for Eagle PCB | https://groups.yahoo.com/group/pcb-gcode/ |

| Auto-trace | Image or bitmap to g-code | http://autotrace.sourceforge.net/ |

| Image to G-Code | Image or bitmap to g-code | http://www.imagetogcode.com/ |

| Scan2CNC | Image or bitmap to g-code | http://www.gravomaster.com/Tristan_Dean/scan2cnc.html |

| MaxCut | Nesting | http://www.maxcut.co.za/ |

Free CNC Software FAQ

What is CNC Software?

CNC Software is the Digital Tooling used to create programs for CNC Machines. There are many kinds, but CAD and CAM are the most common.

What is the minimum CNC Software for a Beginner?

A beginning CNC’er needs to learn to use CAD Software for creating designs, CAM Software to convert the designs to g-code, and Feeds and Speeds Software to determine the proper cutting feeds and speeds for their CAM software to use.

What is the most popular CAD Software for CNC?

Fusion 360 followed by Solidworks are the most popular CAD Software packages among CNC’ers according to CNCCookbook’s CAD Survey. Fusion 360 is free for non-business users and some small business users.

What is the most popular CAM Software?

Fusion 360 is the most popular CAM Software followed by Vectric/Aspire and Mastercam according to CNCCookbook’s CAM Survey. Fusion 360 is free for non-business users and some small business users.

CNC is at the heart of the maker community. By using simple tools like CNC mills, laser cutters or routers, you could create anything from stencils to laser-cut jewelry. But did you know that there’s a 3 step process to CNC? Not only do you need to create a vector with CAD, you also need CAM software and CNC control software to bring your project to life. It can be difficult trying to navigate the choppy waters of CNC software, so Scan2CAD has done all the heavy lifting for you.

This handy guide aims to explain what types of software are involved in CNC—from CAD to CAM to CNC control software. We’ve even included examples of top software and freeware that you could be using with your CNC projects. We’ll even show you where you can find free DXF designs to start your own projects.

- CNC: Overview

- 1: CAD Software

- 2: CAM Software

If you didn’t already know, CNC stands for Computer Numeric Control. CNC machines work by removing material from the initial piece, as opposed to adding new material to it (such as in 3D printing. CNC can be described as a type of subtractive manufacturing and a process such as 3D printing can be described additive manufacturing.

Examples of CNC machines include mills, routers, plasma cutters and laser etchers. For a better look, check out Scan2CAD’s comparison of CNC machines.

Your CNC machine runs on a series of pre-programmed commands. The most common programming language is called G-code, though other languages like Heidenhain and Mazak exist for CNC.

G-code controls the movement of your CNC machine’s tool. It controls its position and depth on the X, Y and Z axes. It also controls the speed at which it rotates and the rate at which it moves.

From Design To Fabrication

Typically, there’s a three step process to CNC that involves three corresponding types of software. To begin, you first need a design in a vector file format (unless you already have the G-code). A vector is a set of mathematical instructions that will dictate how your image is rendered—the most popular vector file format is DXF. You can create your designs and vectors with CAD software. Alternatively, you can use software like Scan2CAD to convert a raster design to a vector.

Once you have your vector, you will need to convert it to G-code which is a programming language that directs your machine. This can be done with CAM software. The process then ends with CNC control software which will read your G-code and turn it into motion to run your CNC machine.

Of course, there are exceptions to the above process. For example, you might find yourself using software that integrates both CAD/CAM capabilities. Or, you might want to skip the CAD step altogether by using free DXFs. We have discussed both possibilities below.

If you’re already sorted with CAD/CAM software, or you’re just hunting for the best control software, skip straight to step 3!

Computer Aided Design software is the starting point for most CNC projects—this software is used to create your designs and vectors. There are hundreds of CAD packages available, each with different capabilities depending on which industry you’re interested in. As we have covered before, CAD is widespread across hundreds of industries—from architecture to art to mechanics.

Of course, you need to choose your CAD program carefully. These packages can be expensive, so you’ll want to make sure you’re going to get your money’s worth—so take advantage of free trials and look at reviews. Unfortunately, there can be a steep learning curve for many packages—however, there are online resources that can help you along the way. For example, Scan2CAD offers tips and tricks for AutoCAD and SolidWorks.

For a better look, take a look at the following list of popular CAD software and freeware below.

Popular CAD Software

- AutoCAD: used to create 2D and 3D drawings. It spans across industries including mechanics, architecture and civil engineering. It’s one of the most popular CAD packages in the world.

- SolidWorks: a parametric feature-based 3D modeling software. It can be used for advanced 3D modeling and auto-generated 2D drawings. It’s the most popular parametric modeler.

- Rhino3D: can create, edit and render NURBS curves, surfaces, solids and polygon meshes. It includes free-form 3D modeling tools alongside complete accuracy and accessibility.

This list of course, is just the tip of the iceberg. If you’re looking to branch out into cloud-based CAD for example, you might like to try a package like Onshape. You should also bear in mind that some CAD packages offer CAM capabilities. Fusion 360 for example, includes built-in CAM software that allows you to create and edit G-code.

Free CAD Software

If you’re not looking to fork out money for a CAD package, you might find it more worthwhile to try out free CAD packages. This is a preferred option for many CNC hobbyists who don’t use CAD software enough to warrant paying a large expense.

Screenshot of Wings3D

Best Cnc Software For Diy

- Google Sketchup: it’s not technically a CAD program, but it does allow you to produce 3D drawings that you can use with a CAM program to create G-code.

- Wings3D: a modeling tool designed primarily for the creation of 3D models, which can then be imported into a CAM program. It supports mesh tools, design and editing features etc.

- NanoCAD: offers 2D, 3D and parametric design—you can build anything from machine parts to blueprints. It’s free, but there are premium versions which include add-on features.

If that’s not enough for you, check out our list of top CAD freeware.

You might be wondering if there’s a way to avoid CAD software altogether. If that’s the case, you’re in luck—you can access free DXFs that are ready-to-cut so you don’t have to design anything. Take a look below to see how.

If you’re looking to start an exciting project from one of Scan2CAD’s CNC project ideas, you might not want to go through the process of creating your own image—it can be pretty time-consuming after all. If that’s the case, you might want to consider using ready-to-cut DXF designs.

There’s a wide variety of free DXF websites that you can download DXFs from to get started on your own CNC project. These include:

A problem you might have with these sites however, is that they will only offer you a finite source—they’re only updated once a month or so. That’s where Scan2CAD comes in!

Scan2CAD isn’t just a conversion software, it’s also a great source for anything CAD, CAM and CNC-related. It’s not surprising then, that we offer our own cut-ready CNC designs that are free and ready to use with your CNC machines. And it’s not just one or two designs—it’s an entire DXF pack every single week—typically containing 6 or 7 designs in a DXF and JPG format.

The theme for each week changes, so you’ll be sure to find something to your taste. Our previous packs have included Ornamental Patterns and American Football. So if you’re looking for a new project to start each week, subscribe today and get DXF packs sent straight to your email.

Computer Aided Manufacturing software is fed your CAD drawing and subsequently produces G-code that you can then feed into your control software to run your CNC machine. It is possible to write G-code by hand for simple circles or lines, but it’s much easier to produce using a CAM program. If you’re still not sure what G-code is, head on over to Scan2CAD’s exclusive guide to G-code.

As we have discussed, there can be confusion as to the difference between CAD and CAM, as many packages like Fusion 360 come with both capabilities nowadays. While it can be more efficient to have an integrated solution, it can be more expensive, which is problematic if you’re looking for a cost-effective package.

Popular CAM Software

- MeshCAM: works with almost every 3D CAD program by opening the two most common file formats, STL and DXF. It boasts more toolpath options than any competing CAM program.

- MasterCAM: one of the most popular CAM programs available. It provides full 3D live wireframe modeling, and a broad range of translators allowing you to open any CAD file.

- OneCNC: provides a CAM system for milling, turning and mill-turn machining. It has versions that provides a range of capabilities in 2, 3, 4 and 5 axis machining.

Free CAM Software

If you’re a casual CNC hobbyist or beginner, you might not need to use the most powerful CAM packages available. After all, you won’t need to figure out 6-axis toolpaths on your first day! With that in mind, the following free packages might be more to your level.

Screenshot of FreeMILL. Image source: MecSoft

- PyCAM: a toolpath generator for 3-axis CNC machining. It loads 3D models in an STL format, or 2D contour models from DXF or SVG files. You can then use the resulting G-code with any machine controller.

- FreeMILL: a free milling module for programming CNC mills and routers. You can run full simulations on your part models and output G-code to your machine.

- G-Simple: is a simple CAM package for 3-axis machining centers. It includes a tools and materials library, along with a selectable excess material removal filter.

Of course, you should bear in mind to be careful when using freeware. Only use freeware that has been reviewed by reliable sources—you don’t want to accidentally download malware. As we have discussed previously with the pitfalls of online converters, freeware can often cause more problems than it’s worth.

Now you’ve had a look at CAD and CAM packages, you might be wondering about packages that integrate both capabilities—or even how you can speed up the entire process. That’s where Scan2CAD comes in once more! Check out step 2.5 below to find out how you can load or create vectors, and convert them to G-code in one single package!

Scan2CAD is a market-leading raster-to-vector conversion software. It supports no fewer than 33 file types, and comes with batch processing, flexible licensing and 24/7 support.

Carbide Create Diy Cnc Software - Free

With it, you can convert your raster designs to a vector file format in a matter of seconds. You can then make use of raster and vector editing suites to create the most optimal vector image you can use for your CNC design. And the best part is, it only takes a matter of seconds. Don’t believe us? Take a look at the animation below to see it in action!

In this animation we convert an anchor image to a vector outline for CNC using Scan2CAD

For more information, check out Scan2CAD’s top tips for taking your design to CNC fabrication.

And that’s not all! Scan2CAD isn’t just useful for converting your files to a vector file format, it can also be used for CAM applications. Once you have a vector you’re happy with (whether it’s one you’ve converted or a ready-to-cut design), you can use Scan2CAD to export it directly to a G-code compatible format. Scan2CAD currently supports three of the most popular G-code file types including: .CNC, .NC, and .TAP.

Scan2CAD also provides a range of options in its CNC Export dialog box, which include:

- G-code Bezier options: cubic splines (G-code G05), arcs (G-code G02/G03) or polylines (G-code G01).

- Arc and circle rotation: clockwise or anti-clockwise.

- Z-settings: various parameters relating to the cutting of the exported vectors.

- Scale settings: the relation between vector points and a distance in real life, e.g. two points on a vector image could represent an inch.

Want a more in-depth look? Take at how to convert an image for CNC with Scan2CAD.

Generally speaking, there are two types of CNC control software: control software built into your machine, and PC-based software. If you were using a commercial CNC machine like HAAS Vertical Machining Center, you would get a complete hardware and software solution that is built into the machine—you’d be able to transfer your G-code directly to the machine. Hobby CNC machines by comparison, have an external controller—by making use of control software, you can turn your PC into a machine controller.

Free 3d Cnc Router Software

When it comes to PC-based controller software, there’s a wide variety on offer. There are a few key controllers that stand out from the crowd however. Take a look below for our top picks, featuring low-cost and free software.

1. The Mach Series

- Cost: $200 (Mach4)

- Controls: mills, lathes, routers, lasers, plasma etc.

- Operating system: Windows

Best Free Cnc Software

The Mach series are at the forefront of CNC control software. The developer ArtSoft has been releasing and improving upon the Mach series for the past decade—the most current version of which is Mach4. This low-cost software works on most Windows PCs, making use of advanced system level drivers to enact pulse timing for stepper motors and step-servo systems.

The software itself is very intuitive and customizable. It can control up to 6 axes of a CNC machine. Previous versions like Mach3 allowed hobbyists to use their license across multiple machines, whereas Mach4 now ties the license to a specific PC. If you are curious about the software, you can test out the free demo mode for up to 500 lines of G-code!

2. LinuxCNC

Image source: Linuxcnc.org

- Cost: Free

- Controls: mills, lathes, 3D printers, robot arms etc.

- Operating system: Linux

LinuxCNC is undoubtedly the direct competitor to the Mach series—it’s certainly a popular option for many CNC hobbyists, and not just because it’s free! Previously called EMC2, this CNC control software is completely open source. And as the name suggests, the software runs under Linux. Due to the need of precise real time control of machines in motion, the software requires a platform with real-time computing capabilities. This means that if you don’t have real time computing capabilities, your PC will only run the package in demo mode.

Freeware can often seem lacking in some way, however that certainly isn’t the case when it comes to LinuxCNC. It can control up to 9 axes of a CNC machine, and has several GUIs suited to specific types of usage such as touch screen and interactive development. The software also supports advanced control features like rigid tapping and cutter compensation.

Free Diy Cnc Software Free

3. TurboCNC

- Cost: $60

- Controls: mills, lathes, routers, laser cutters etc.

- Operating system: DOS

Our final choice for top CNC control software is TurboCNC. This machine control software provided by Dak Engineering runs under DOS. The software itself is shareware—you can gain access to its source code and free support for a low-cost fee of $60.

TurboCNC is an efficient controller that runs stepper motors and step-servos. It can control up to 8 axes of motion, and it comes with configurable I/O for reversible and speed control spindles. It also provides fully parametric programming with variables, subroutines and expressions.

4. Universal Gcode Sender

Universal Gcode Sender (UGS) is the software of choice by a large number of the CNC community. This in-part might be because the software is absolutely free and available on Github.

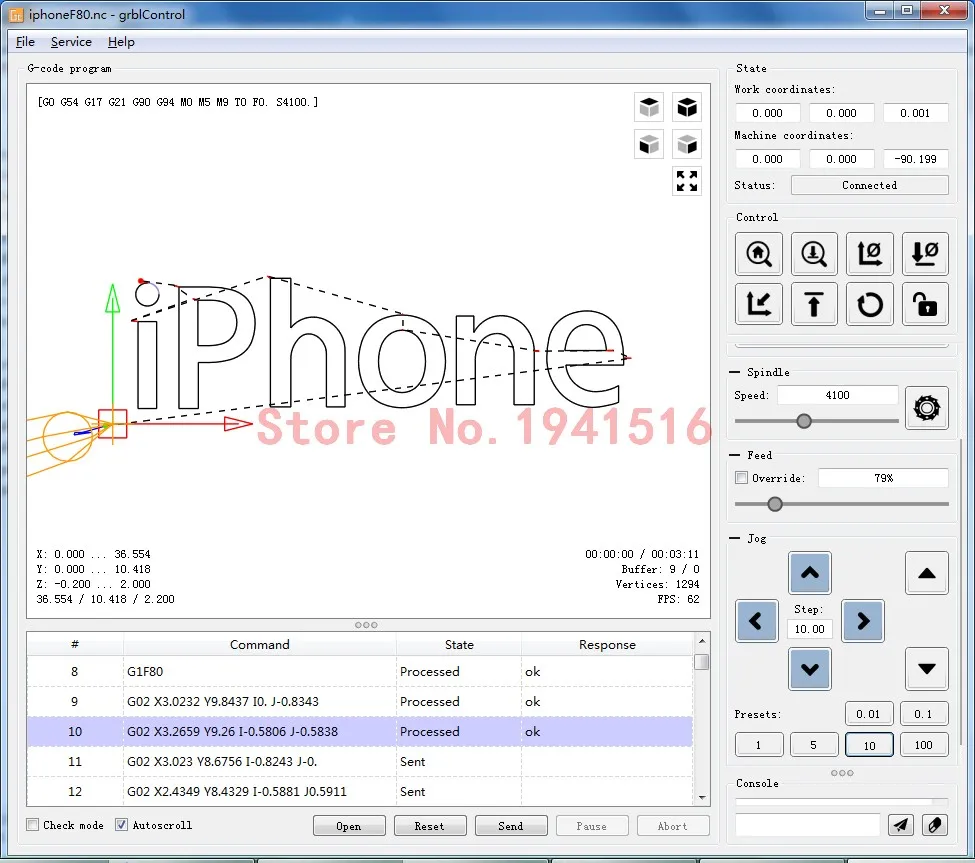

Cnc Programs Free Download

The software has been designed with real-world problems in mind. It comes with ‘configurable gcode optimization’ to remove comments, convert arcs to lines segments, remove whitespaces and more.

- Cost: Free!

- Controls: mills, lathes, routers, laser cutters etc.

- Operating system: Cross platform, tested on Windows, OSX, Linux, and Raspberry Pi.

Other CNC control software includes:

If you want to learn more about the world of CNC, why not check out the CNC section of the Scan2CAD blog? We cover a range of topics from the best CNC kits for beginners to new innovations in CNC.